At Carl Stahl Sava Industries, it’s not uncommon for our engineers to produce not just custom mechanical cable, but rather, also custom fittings, tooling and even machines developed to perform a complex manufacturing process. In many cases, the products Sava’s customers need exist only in a drawing, and therefore must be built from scratch. In the surgical robotics space for example, the robot itself is an innovation. Thus, the motion control cables actuating the instrument’s appendages need to be developed by skilled mechanical engineers as well. But as importantly, automation engineers need to solve sophisticated mass production processes used to manufacture the robot's mechanical cable components, and likewise ensure they comply with rigid regulatory standards too.

Common Cable Fittings in Unique Production

Many industries utilize custom mechanical cables that can accommodate stock fittings, but often, even the most stock components require innovative production equipment to yield world-class quality straight on through the assembly line. Take, for example, an endoscopic cable assembly that needs to be cut to length, possess complex cut ends, and from there, collected and bundled. While the cable-strand process may follow a more time-honored manufacturing process, the way with which the finished cable assembly is automatically readied to the customer’s specifications is a matter of sophisticated automation engineering expertise.

Industries requiring unique production environments, but commonly comprising typical cable and cable components include:

- Surgical Robotics

- Medical Devices

- Aerospace

- Aviation

- Defense

- Military

- Industrial Equipment, Vehicles and Machinery

As a matter of fact, mechanical engineers are tasked daily with uncovering ways to help customers not merely realize their cable assembly ambitions, but also account for the litany of production unknowns that may not be accounted for in a technical drawing. Ways a length of cable is terminated, stretched, reduced in diameter, are all among the many challenges automation and mechanical engineers must weigh when satisfying the total product ask.

_3nd.png)

Explore Production Options

Regardless of the commonality, or rarity, of a given cable fitting or assembly, once a working prototype is ready, the mechanical engineers at Sava investigate the best way to produce the product over and over, at the highest possible quality and reliability. In automation, among the urgent priorities is determining a way to produce the mechanical cable components as fast as possible, but do so at a consistently high quality. Therefore, it is ideal that production requires as few steps as can be achieved in a production run. Automation engineers at Sava reduce the number of steps in a production process by trying to combine steps into a single machine, so, for instance, the product only needs to be handled once, rather than a number of times, which may introduce potential time, resource and ultimately, money to an otherwise lean manufacturing process.

A less ceremonious task for Sava’s engineers is the obligation to reduce waste everywhere it can be done responsibly. If the engineer forgoes consideration for such mission-critical duties as even saving time, then perhaps that slowing in production adversely impacts the customer’s ability to compete in ambitious, global markets. And even were the customer free to compete aggressively, wasted steps in production may put manufacturers at risk of giving up opportunity to a nimbler alternative.

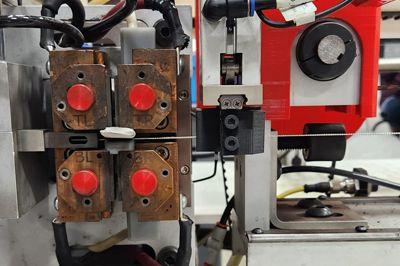

The final step in preparing to manufacture custom cable and wire rope fittings for our customers is the creation of the custom dies and machinery that will be used in full-scale production. While no two customer requests may need exactly the same fittings, the experience, techniques and equipment created for each one can be applied to future projects, adding to manufacturing efficiency.

Custom Production Means Reliable, Quick Outcomes

- While a mechanical cable assembly may comprise even the most common components, the production environment designed to create them is often extremely customized.

- In custom production processes, among the chief engineering ambitions is achieving a high production rate. This means steps need to be reduced, not added.

- Keeping customers competitive often involves manufacturing engineers that know how to design production processes that save precious resources like time and eventually, money.

At Sava, we are committed to creating high-quality wire rope, mechanical cables and cable assemblies using the most sophisticated production process. Contact us today to learn more about our cable and wire rope capabilities and see how our customizable production can bring your design to life.