Swaging stainless steel cable is a mechanical process used to reduce cable diameter. Here's a look at the wire rope swaging process, why you might want your stainless steel wire rope swaged and qualities of swaged stainless steel cable.

The Wire Rope Swaging Process

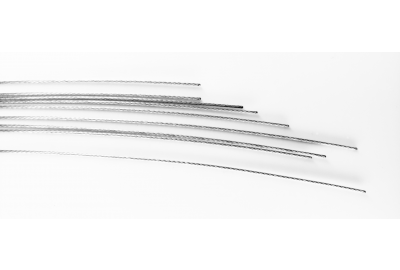

Mechanical cable is made by twisting individual wires together in a helix to produce strands. These strands are then twisted around a central core to make wire rope. Swaging is the process of taking this rope and hammering its outside diameter to compact and flatten the strands.

Cable swaging is done in a rotary swaging machine. The cable is fed through the center of this sophisticated piece of manufacturing equipment. Inside the swager are a pair of hammers 180° apart that oscillate in and out, as the swager rotates. This repetitive action makes the cable diameter smaller. There are other benefits to swaging, which include improving the straightness and stiffness of the cable, as well as preventing it from fraying.

Why Have Wire Rope Swaged?

Here are 3 instances in which you would get wire rope swaged:

- 1. The smoother surface runs over pulleys more easily and slides better inside sleeves, reducing the force needed for movement.

- 2. Push-pull applications need stiffer rope or cable so they do not buckle when pushed.

- 3. The wire rope swaging process prevents fraying when the cable is cut.

Characteristics of Swaged Stainless Steel Wire Rope

As discussed, swaging reduces the diameter of mechanical cable by compacting the strands and individual wires. This increases stiffness, takes out any bend created during the stranding process and smooths the outer surface.

Industries that use Swaged Stainless Steel

Medical cable assemblies often use swaged cable. Here the smooth surface achieved with swaging provides the frictionless movement many instruments require. Plus, some devices require a push-pull action, where the ease with which cable moves over pulleys and inside conduit is critical to the performance of the device.

Swaged, stainless steel cable has been used in orthodontics, where again the smooth surface and stiffness of the cable improve function.

Learn More About Swaging Mechanical Cable

At Sava, you’re working with swaging experts. To learn more, contact us today.