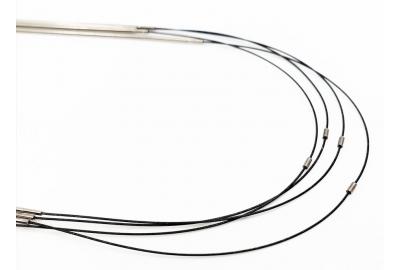

Hypodermic needle tubing, generally referred to as hypotubes, are used in numerous medical applications, such as catheters, needles, cannulas and mechanical cable stops. In the mechanical cable industry, hypo tubing is used to join cable segments together or to act as a load-bearing point on a mechanical cable assembly. Hypotubes can be swaged to cable made from any alloy, but is most commonly used with stainless steel and tungsten cables in the manufacture of surgical robots and medical cables and instrumentation.

There are numerous stock sizes of hypotubes available to the design engineer, both in 304 and 316 stainless steel, seamless and welded as drawn. Custom sizes may be manufactured to suited specific applications, as required.

As the demand in surgical robotics and medical instrumentation requires ever-smaller profiles from its mechanical cables, hypotubes provide an off-the-shelf solution to these increasingly more complex application requirements.

Technology has also contributed to the production of quality tubing used in surgical robotics. Because of the tight tolerances required on swaged tubing, technologies such as laser cutting allow engineers to control finished dimensions and tolerances of critical motion control components. Through this technology, engineers can produce hypotube cable assemblies comprising any diameters, while still achieving superb quality. Medical equipment manufacturers are, therefore, keen on using the right material and technology to produce market-standard hypodermic tubing.

The following are key design characteristics that must be balanced well in the manufacture of these sensitive medical applications.

Kink Performance

One of the most important features of hypotubes that manufacturers must factor in is kink performance. Kink resistance is a device's ability to maintain its cross-sectional profile during compressive deformation. A strong tubing must have good kink resistance to navigate through the body. This can be achieved by enhancing the material's ductility to increase its strength and resistance.

Transition

Laser cutting helps maximize medical hypotubes' transition performance. Transition is the change in stiffness from the proximal shaft to the distal shaft. This is achieved by removing some material from the distal end to make the device more flexible as it moves through the body.

Trackability

The trackability of the hypotube is a crucial property that suppliers must put into consideration. Trackability measures what the physician will feel when manipulating the device. Low tracking allows for easier manipulation and positioning. The physician should be able to move the device through the body with less friction. This can be enhanced by incorporating several features.

For instance, employing superior coating technologies will ensure the devices have a smooth coating. The tubing diameter should also be reduced as well as the thickness of the outer wall. These properties are key to reducing patient trauma.

Push and Torque

Another key characteristic of medical hypotubes is their push and torque quality. This refers to the ease with which a physician transmits the device from the proximal end to the distal end.

To achieve optimal pushability, the device material should have great tensile strength. The 304 and 316 steels used in making hypotubes have good tensile potential. With the right metal treatment, their strength can be optimized.

Key Takeaways

-

Manufacturing cable assemblies that include hypotubes requires great precision to achieve quality medical instruments.

-

Laser cutting helps in the manufacturing of hypotube used in the making of medical cable assemblies.

-

Hypo tubing is used extensively in the manufacture of stainless steel and tungsten surgical robotics cable assemblies.

-

Ever-shrinking cable assembly profiles are more and more common. Hypodermic needle tubing provides a solution within those narrowing spaces.

At Carl Stahl Sava Industries, we utilize cutting-edge laser technology to manufacture high-quality hypotubes that improve the medical experience for both the physicians and their patients. We work with customers from across the globe to deliver custom designs for both common and exotic medical industry cables. You can trust our time tested experience as manufacturers and suppliers of custom cable and cable fittings to design and manufacture your hypotubes. Contact us today!