Precision applications call for precision materials, and tungsten wire rope is the ideal high-strength robotics cable for precision applications. For decades, stainless steel has been the go-to metal for manufacturers who needed resilient and anti-corrosive material, especially in moisture-rich settings. Stainless steel has high tensile strength and is cost-effective, making it the perfect choice for wires and cables that have to endure extremely harsh environments and working conditions. Stainless steel is valuable because it is durable and retains its integrity.

However, tungsten wire has become the industry favorite for surgical robots.

Tungsten Wire and Its Properties

Due to tungsten wire rope’s properties, everything that stainless steel can do, tungsten can do better (for the most part).

Tungsten has the highest melting point of any known metal at 6,192 degrees Fahrenheit. On the other hand, stainless steel melts at 2,750 degrees Fahrenheit and anneals at 1,900 degrees Fahrenheit.

Tungsten's tensile strength is superior to stainless steel. In the mechanical cable industry, it’s common to see tungsten with 25 percent greater tensile strength for equivalent diameters in constructions.

Tungsten is also superior to stainless steel when it comes to abrasion resistance. Due to its structure, tungsten has a much longer practical life, especially when it's applied to a cable assembly or cycled over a pulley. Cables made from tungsten wire are much more likely to last long-term than products made from stainless steel. Tungsten has incredible qualities when it comes to longevity, resistance, and strength, making it the ideal choice for surgical robots.

Why is Tungsten Perfectly Suited for Surgical Robots?

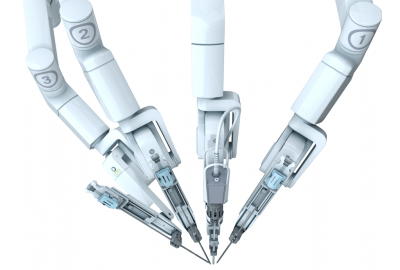

Because of the aforementioned qualities, tungsten is perfectly suited for medical device applications. Surgical robots are expensive, high-end devices that simulate the motion of a surgeon's hand. These robots depend on actuators to open and close finger-like appendages repeatedly over the course of an operation.

The cable assemblies that are used inside surgical robots require materials with a high level of reliability. While heat resistance is not an important feature when it comes to surgical robots, the tensile strength, extreme flexibility and abrasion resistance are a necessity for minuscule cable assemblies that require a high level of reliability over long periods.

What are the Strand Requirements for Surgical Applications

Surgical tungsten cables are required to perform for 1,000 cycles during a single surgery, as they power the actuators responsible for articulating the complex and dexterous actions necessary to complete the procedure.

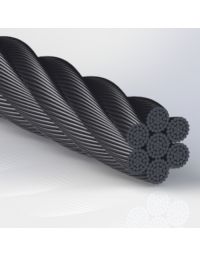

Tungsten cables are made from tungsten wires, which involves wrapping multiple tiny wires or filaments together into a larger cable strand. These strands are then wrapped together to form completed mechanical cables. Because surgical robots require such limber internal mechanics, the tungsten cables involved can be comprised of as many as 700 wires, with a diameter as small as .0005 inches. Tungsten cable constructions may use more complex configurations like 7x37, 19x19 and 19x37 to increase their flexibility and durability.

Takeaways

-

Tungsten is a stronger and more versatile material than stainless steel

-

The ultimate tensile strength of tungsten is much higher than stainless steel

-

Tungsten has a high melting point, is anti-abrasive and is extremely flexible

-

Due to its qualities, tungsten wire is commonly used in surgical robots

-

Surgical cables require a material that can go thousands of cycles with high reliability

Related Content:

The Benefits Of Tungsten Cable

Tungsten Cable For Surgical Robotics

Cutting Tungsten Mechanical Cable

Carl Stahl Sava Industries can work with you to design a high-strength, long-lasting tungsten wire rope assembly for your surgical robot application. Contact us today to get started with your cable design.