For Over 50 Years, A Trusted Mechanical Cable Maker...

Since 1972, Sava's produced the wire rope and mechanical cable Assemblies for the world's surgical, MedTech and industrial leaders.

A Customer-Driven Wire Rope Manufacturer and Supplier

A wire rope and mechanical cable manufacturer and supplier, Carl Stahl Sava Industries excels in providing custom mechanical cable assemblies, cable fittings, and cable pulleys. For over five decades, our commitment to innovation, quality, and customer satisfaction has made us among the top choices with mechanical and robotics engineers.

As a customer-centric wire rope manufacturer, Save recognizes the distinct challenges and demands that engineers face while developing motion control systems and load-bearing applications. That’s why our cutting-edge manufacturing facilities are outfitted with the latest technologies and operated by a team of world-class wire rope experts.

Our comprehensive engineering services include design consultation for the most complex MedTech cable assemblies, as well as the rigorously regulated industrial, aerospace, and commercial sectors we support. Sava offers various fitting options, such as crimp sleeves, threaded plugs, eyelets, and many others. Sava also provides wire rope prototyping kits for unproven systems still under development.

Additionally, Sava’s cable pulleys are designed to deliver exceptional performance, even in the harshest environments.

Our experienced, in-house engineering team collaborates closely with clients to develop tailored cable solutions® that adhere to the precise design and regulatory specifications our customers require. Our commitment to close collaboration, from the first meeting to production shipments, guarantees that Sava is always supplying the finest cable assemblies and hardware the world can produce.

As a global frontrunner in wire rope manufacturing and supply, Sava has earned a reputation for delivering outstanding products and unmatched customer service around the globe.

Over a Half Century of Mechanical Cable And Fittings Manufacturing Experience

Over a Half Century of Mechanical Cable and

Fittings Manufacturing Experience

At Carl Stahl Sava Industries, manufacturing a comprehensive family of wire rope and mechanical cable fittings and tools only explains a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages over 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s technical sales and engineering professionals boast over 100 years of combined technical experience, helping organizations just like yours meet the most complex and sophisticated application requirements.

Discover Our...

Custom Assembled Solutions

Tap into our deep understanding of cable construction and application dynamics. We design, manufacture and test custom assemblies for highly complex application requirements.

Product Categories

A cable supplier for clients spanning the globe, everyday Sava meets the diverse needs of its customers with an extensive selection of product categories, ranging from precision miniature cables to large pulleys.

Expertise

Leverage our expertise in design and application information for guidance in making the best purchase decisions.

Markets Served

Medical and industrial manufacturers and other markets rely on both Sava's products and expertise. Get familiar with the wide breadth of industries we serve.

Shop By Category

Assembled Solutions

Sava possesses unique custom cable assembly expertise and fully customized solutions

Precision Miniature & Small Cables

Sava works with a wide range of materials, diameters, constructions and extruded coatings for your custom wire rope assembly

Mil Spec

Trust Sava to ensure you achieve the performance demands of your products

Push-Pull Assemblies

Sava's reputation is backed by a half-century legacy of push-pull control cable expertise

Fittings

Sava meets your evolving challenges by adapting the fitting and assembly demands based on your unique circumstances

Our reputation as a leading wire rope assembly manufacturer is strengthened by the long-lasting relationships we build with our clients. Explore our products, collaborate with our team for your custom assembly, or click the button below and get in touch with us to discuss your next wire rope project.

Featured Category

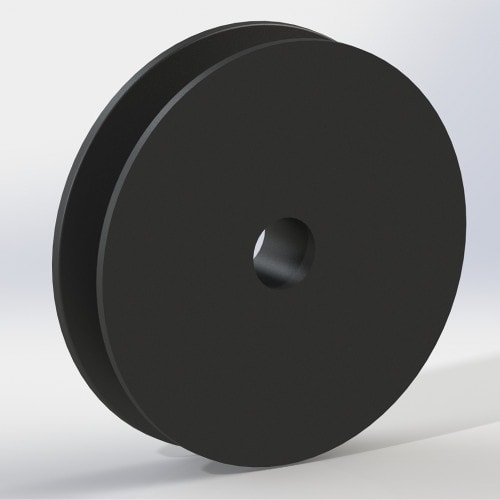

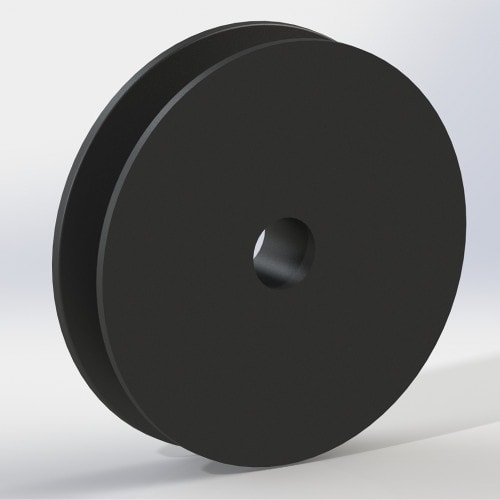

BP Series pulleys are made of Delrin. The chemical composition and the highly crystalline molecular structure of Delrin is the key to these pulleys physical properties. The high mechanical tensile strength and rigidity, natural lubricity, high resistance to moisture, gasoline, oil, UV impact, and neutral chemicals makes these pulleys highly durable. Moreover, high resistance against deformation due to heat impacts (up to 230° F) and good electrical insulating are further characteristics.