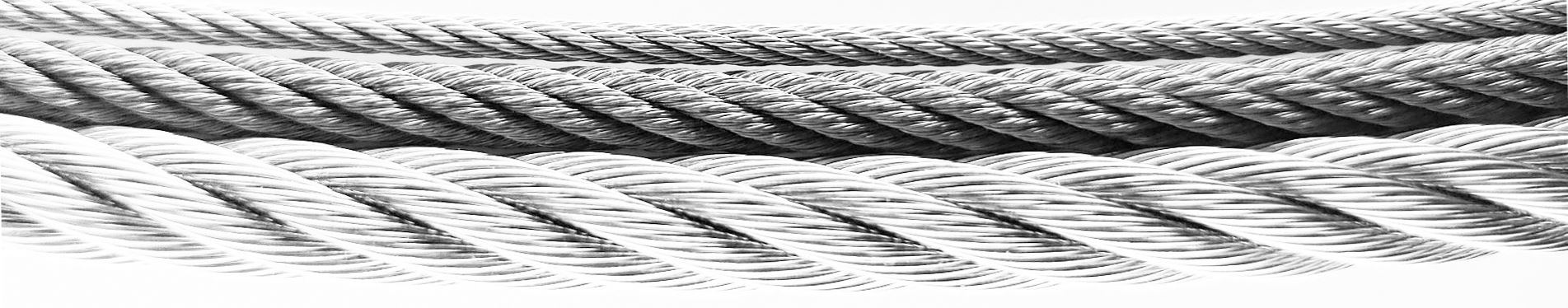

Unparalleled Strength and Versatility: Exploring the Application Benefits of Galvanized Steel Cable

Galvanized steel cable has become a staple in various industries due to its numerous application benefits. This highly versatile material offers strength, durability, and affordability, making it a top choice for many applications that require reliable and cost-effective cable solutions®.

One of the most significant advantages of using galvanized steel cable is its scientifically proven break strength. During the manufacturing process, galvanized wires are coated in a layer of zinc, which ensures the cable possesses remarkable tensile strength. Sava achieves break strengths as low as 110 lbs. with a 3x7 construction, at a diameter of .03125" (.813mm). On the high side, Sava reaches 14,400 lbs. with a 7x19 construction, at a diameter of .375" (9.53mm). These strengths make galvanized steel cable an ideal choice for demanding applications where strength and reliability are crucial.

The chemical makeup of galvanized steel cable plays a vital role in its impressive performance as well.

The steel core provides the cable with its inherent strength and rigidity, while the zinc coating adds an extra layer of protection against corrosion and wear. This combination of materials results in a cable that can withstand harsh environmental conditions and resist rust, ensuring a longer lifespan and better performance in comparison to other cable types. A word of caution however would be that galvanized steel cable will perform poorly in marine environments where saltwater or salt vapor are present.

Providing salt content is not present in the environment, the zinc contained within galvanized cable means the wire rope possesses a highly reactive metal that forms a protective barrier when exposed to oxygen, preventing the underlying steel from corroding. This process, known as galvanic protection, is especially useful in outdoor applications where cables are exposed to moisture, humidity, and other corrosive variables.

In addition to its corrosion resistance, galvanized steel cable offers an excellent strength-to-weight ratio. This characteristic makes it a preferred choice for applications that require strong, yet lightweight materials. For instance, the construction and infrastructure sectors often employ galvanized steel cables in the form of suspension bridges, cable-stayed bridges, and various support systems. In applications not as large as bridges and other roadway infrastructure, galvanized steel cable does well in counterbalancing systems, as well as scaffolding, gantry, and other above-the-head hanging apparatuses.

What’s more, galvanized steel cable is well known for its ability to support the mining, oil, and gas industries that rely on cable to perform various extraction and hauling tasks.

To ensure the galvanized steel cable used in your system meets your application needs, contact Sava’s engineering team now.

Sava's Galvanized Steel Cable Constructions

Sava has been making galvanized steel cable since our modest begnnings 50 years ago. Check out our line of constructions offerings. Also, visit our over-the-counter galvanized cable products for speedier turnaround.

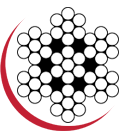

1X19

19 wires, is stiff and common in signage, lanyards and guy wires.

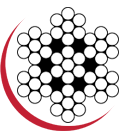

7X7

49 wires, is medium flexible and common in industrial acutators and linkages.

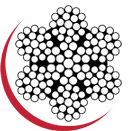

7X19

133 wires, is flexible and common in counterbalancing and pulley applications.