Sizes and Specific Offerings

Sava has full stamping capabilities from .001 inches up to .187 inches thick, along with tensile strength up to 316. Metal stamping product width can range up to a full six inches. In terms of maximum output, we can handle any project up to 45 tons of stamped metal parts, allowing for a wide variation in terms of size and scale to meet nearly any project needs.

Metal Stamping Materials

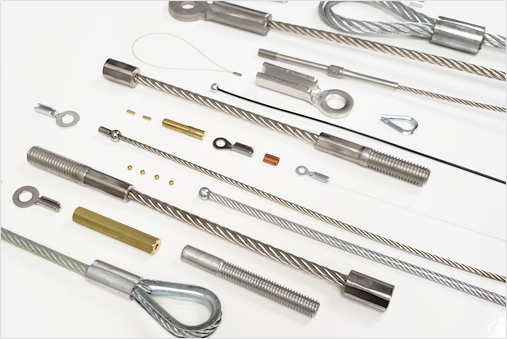

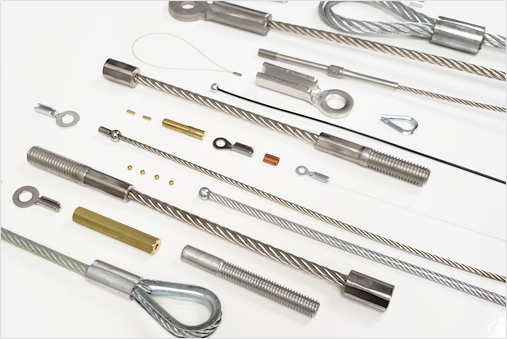

Offering customers a diverse array of products, produced from as varying a family of materials is a crucial component of Sava’s metal stamping services, We're proud to offer metal stamping services for an assortment of different metals, including various grades of carbon steel, stainless steel, specialty steels, copper, aluminum, brass, tungsten (chrome alloy or constantan aluminum) and many others.

Speed-to-market

In a frantically competitive and fast-paced global economy, we understand that speed is critical to every customer's business. As a matter of fact, speed-to-market is almost always among the very first points of pain incoming, new Sava customers express to us.

And as importantly, with Sava, speed never comes at the sacrifice of quality when it comes to precision metal stamping services. As some complex parts simply have longer time requirements, Sava proactively works with sourcing partners to anticipate the urgency with which you are competing. Often enough, such aggressive production planning from Sava ensures your company can compete amid markets fiercely eager to take market share from you. Since all of Sava’s operations are done in-house, the middleman is largely cut out, thus saving our clients time and money when they matter most.

Looking to balance the need for speed with our always high expectations for quality, Statistical process control (SPC) data collection provides real-time measurements that keep our metal stamping processes running smoothly and efficiently. Sava’s preventative maintenance program is also part of our proactive philosophy to ensure our machines are in top-notch order, helping keep delivery timetables, which helps build trust with our customers.

Value and Price Propositions

Among the many reasons Sava’s developed a loyal metal stamping customer base is because they know they're getting a fair price and excellent all-around value. Over 50 years in business, Sava has seen first-hand how important it is to stay on top of shifting industrial trends, and we offer a combination of experience and technical expertise that helps customers stay both on-budget and ahead of the competition.

By limiting waste and keeping process time to a minimum, Sava stays focused on the quality and value of every product we make for you.

Although Sava has built a reputation as a global leader in cable and fittings manufacturing, our metal stamping services have been a bedrock of operations since the company's founding. Contact us to learn more about how Sava can help with all of your metal-stamping needs.