What Goes Into Cost?

Cable Construction

Prevent corrosion, rust, and chemical reactivity, and in so doing ensure the optimal lifespan of your cable system. Sava proudly offers passivation services for all of our cable, fittings, and cable assemblies. Fewer wires in a cable results in lower cost, but also less flexibility. Hence, a 1x19 (19 wires) will be less expensive than a 7x7 (49 wires), but the latter will be more flexible than the former. Likewise, a 7x7 will be less expensive, but less flexible than a 7x19 (133 wires) in the same diameter. Striking the right balance between cost and technical requirements is a delicate exercise that Sava can guide you through.

Material

Using standard 302/304 stainless, stainless steel cable will cost approximately 1.5 to 3x more than galvanized steel cable, depending on the size and construction. Coated galvanized steel wire rope will generally cost less than an equivalent stainless steel cable and even coating informs the price. For instance, vinyl coating is less expensive than nylon, and FEP is the most expensive. Contact Sava’s sales team to discuss these and other types of cable and coating materials.

Strength Recommendations

Even the number of manufacturing operations influences pricing. Take, for example, the full-rated strength of your cable assembly drawings. You can save money if the cable fittings are applied directly to the coating, which equates to a reduction in the individual operations required to produce the part. Although, as much as a 35% diminishment in strength will result, the assembly may still achieve a passable factor of safety, and cut costs at the same time.

Length Tolerances

Tolerances are an important cost consideration as well. Tight tolerances require more expensive cutting processes and more rigid inspection criteria. For that reason, cable assemblies requiring precision tolerances must define the load under which the cable is to be validated. Talk to Sava's engineering team about your tolerance requirement.

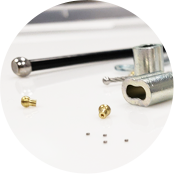

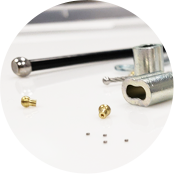

Fittings

Carl Stahl Sava Industries offers a vast scope of premium mechanical cable fittings, skillfully designed to serve the requirements of numerous motion systems. Sava's superior understanding and commitment to quality regulations during manufacturing ensures that our cost-efficient fittings deliver reliable performance and long-lasting results for your cable assemblies. Listed from most cost-effective to least, our cable fittings include eyelet, ball-end plug, threaded plug, ball, ball & shank, loop, and a variety of mil-spec terminals.

Recommended Length Tolerances

| LENGTH (FT.) |

TOLERANCE ± (IN INCHES) |

|||

| PRECISION | TIGHT | CLOSE | STANDARD | |

| 0.1 - 2.0 | 1/64 | 1/32 | 1/16 | 1/8 |

| 2.1 - 5.0 | 1/32 | 1/16 | 1/8 | 1/4 |

| 5.1 - 10.0 | 1/16 | 1/8 | 1/4 | 1/2 |

| 10.1 - 20.0 | 1/8 | 1/4 | 1/2 | 1 |

| 20.1 - 40.0 | 1/4 | 1/2 | 1 | 2 |

| 40.1 - 60.0 | 1/2 | 1 | 2 | 4 |

| 60.1 - 80.0 | 1 | 2 | 4 | 8 |

| 80.1 - 100.0 | 2 | 4 | 8 | 16 |

| 100.1 AND ABOVE | .5% of length | .8% of length | 1.5% of length | |

Talk to our world-class engineering team and discuss your project's technical requirements and let Sava help develop a cost-effective plan to proceed.

Let's discuss your next project or get a quote today!