Providing Compliant, Quality-Assured Aircraft Cable & Cable Assemblies for the Aerospace Market

Carl Stahl Sava Industries knows it’s not enough to ensure your aircraft cable & cable assemblies maintain standards set by the International Organization for Standardization (ISO), as well as a host of other critical quality processes in the design of aerospace cable assemblies.

At Sava, we know that aerospace cable assemblies designed for military operations and aircraft control require something more. You need an aircraft cable manufacturer that possesses a proven understanding of both cable construction, as well as the unique requirements of custom cable assemblies in aerospace, government, and commercial applications.

Work with a cable assembly manufacturer that has powered air travel, space exploration, and military defense projects for over 50 years. Sava is DFAR compliant and ITAR registered, and provides first-article inspection reports in AS9102 format.

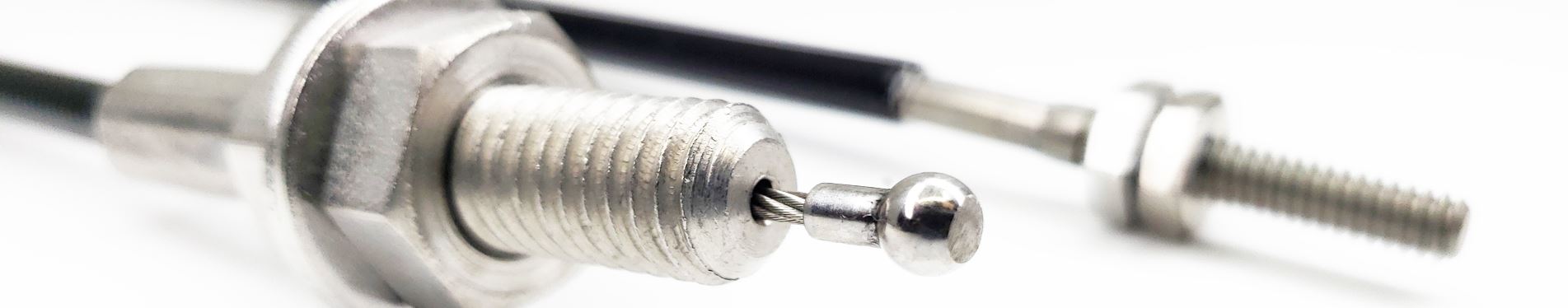

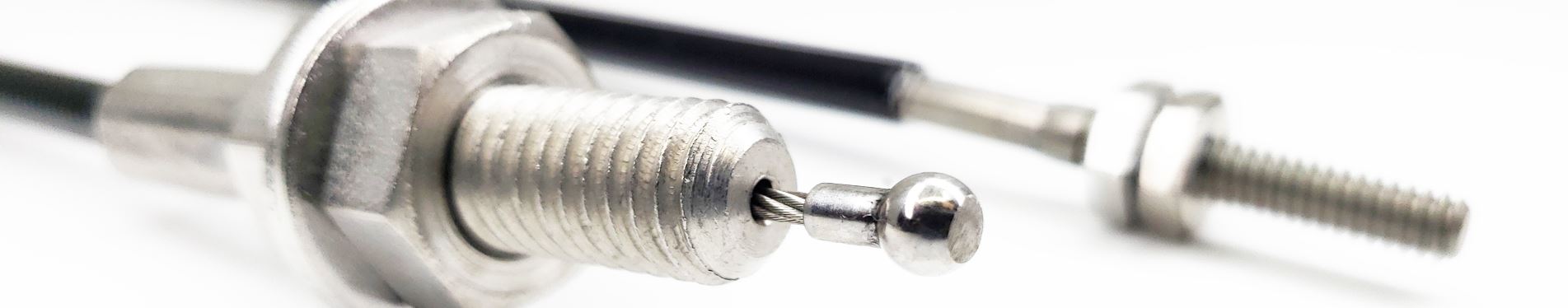

We are an aircraft cable & custom cable assembly manufacturer offering a comprehensive range of mil-spec cables and aerospace standard fittings, and providing products that comply with the MIL-T-6117 and MIL-T-781 standards as well. However, our aerospace standards wire don’t simply fulfill important requirements for military or commercial aircraft applications, Sava is also committed to meeting the exact requirements of your aircraft cable assemblies, no matter how custom or complex.

When designing cables for aerospace applications, it is critical to use trusted aircraft cables with proven results that meet the unique application requirements of aerospace engineering. Aerospace is an industry where heightened sensitivity and attention must be given to aerospace wire and cable by cable assembly manufacturers because it is used typically in matters impacting the safety of human beings.

What is Mil-Spec Cable?

The key to understanding the importance of cable quality used in aerospace applications is rooted in an understanding of the stringent guidelines under which that type of cable is produced. Cable assemblies used in commercial and military-grade aircrafts are subject to different and rigorous oversight than are mechanical cable assemblies used in products not involving flight or defense instruments and devices.

This type of cabling is manufactured with the intention of being used in extreme conditions. The integrity and functioning of the cable assembly must be of the highest quality. This type of cable is called "Mil-Spec," which stands for "Military Specification."

MIL-DTL-83420 is the Military specification standard that governs the vast majority of aerospace cable applications. Within this specification is a series of testing protocols that must be approved prior to the cables being made available for sale. This battery of tests include evaluations of endurance and breaking strength. Providing the cable undergoing testing satisfies these strict quality requirements, the product is sent to market.

Aircraft Cable Assemblies and Spacecraft Assemblies

The cables created for aerospace applications aren’t always addressing life-saving or control issues. Sometimes MIL-Spec cables are performing comparatively ordinary functions such as keeping interior doors from swinging wildly in flight. However, the same MIL-Spec cable is also used for complex and high-risk projects as well. In such examples, cable may be used to support the deployment of a city bus-sized, solar sail found on space satellites.

One of the requirements of MIL-Spec cable is that it incorporates lubrication in the manufacturing process. To achieve the best-possible life out of the MIL-Spec cable, a lubricant is applied during the standing of the wires that comprise the cable. In addition, the lubricant helps to weatherize the bare metal in the wire rope, shielding it against corrosion. While it is always advantageous to protect cables for environmental conditions, MIL-Spec cable is required to possess such lubricant within the MIL-Spec cable’s construction.

Mil-Spec in Space

Things change, however, when you put MIL-Spec cable in space. In zero gravity, the grease from MIL-Spec cable can migrate from the cable surface, potentially contaminating the craft's breathable air and surfaces.

Measures can be taken to minimize these effects in space. Those measures include cleaning the cable thoroughly prior to its installation. Some of these methods include ultrasonic cleaning, vapor degreasing and other solvent-based removal processes. Another option would be to consider the use of commercial-equivalent cables, which are not impregnated with grease during manufacturing, but maintain the same integrity as MIL-Spec alternatives.

Sava’s products, which adhere to strict design standards and specifications, are used in all types of applications within the aerospace industry.

Why Choose Sava Cable as your Aircraft Cable Assembly Manufacturer?

Sava adheres to the strict testing guidelines necessary to craft a quality product that stands up to commercial, industrial and aerospace applications. Our engineers can help you design a custom mechanical cable solution that fits your specifications. Please contact us today to find out more about our aerospace cable products.