Push Pull Control Cable Manufacturing Expertise

Push-Pull Control Cable Assemblies That Exceed Your Requirements

Too much cable contained within the control cable conduit may result in unwanted slack, kinking, and backlash. Unfortunately, too often these are the consequences of a poorly conceived push pull cable assembly design. As easy as it may seem to produce control cable assemblies, any small variation in conduit ID, or cable diameter can mean failure in the field. As a control cable and push pull assembly manufacturer, Sava understands the inherent challenges in producing a world-class control cable assembly. That is why Sava focuses on providing customers with our time-tested engineering expertise, which focuses on creating the right push pull cable assemblies the first and every time. Our in-house team of engineers meticulously reviews your control cable design and provides suggestions and value-added services when appropriate. This not only improves the outcome of your production run but also enhances the lifetime performance and durability of your products.

SOME OF OUR CONTROL CABLE & PUSH-PULL COMPONENT APPLICATIONS INCLUDE…

AEROSPACE

APPLICATIONS

EQUIPMENT TO OPEN

AND CLOSE DOORS

FIRE SUPPRESSION

MECHANISMS

ACCESS SAFETY

LATCHES

SAFETY BRAKE

DEVICES

THROTTLE

CABLES

Providing Services That Add Value to Your Push-Pull Components

As an experienced cable assembly manufacturer, Sava understands how application dynamics and even the smallest detail can impact your push-pull components and the assemblies. This is why Sava's engineering and production experts offer…

Proof Loading and Prestressing

Your custom control cable assemblies need to be tested for optimal performance and fitness for your application. Sava knows this. So, we will mitigate the effect of constructional stretch with our proof loading and prestressing value-added solutions.

Break-Strength Testing

Tension failures are unacceptable in any production run. That’s why Sava offers state-of-the-art, break-strength testing solutions, ensuring your control cable assemblies meet or exceed your tension failure requirements.

Passivation

Prevent corrosion, rust, and chemical reactivity, promising your cable assemblies to meet the lifespan your applications demand. Sava proudly offers passivation services for all of our cable, fittings, and control cable assemblies.

Browse our push-pull components, including our solid wire, controls, and terminal solutions now.

Finding the Right Push-Pull Components

While choosing the right services is important to assure optimal application performance, your push-pull assembly design plays a critical role. Take a moment to understand the design factors that go into buying the best push-pull cable assembly products.

Cable Constructions, Loss of Motion, Travel, Bend Radii and Life

In addition to manufacturing control cables that support a variety of push pull applications, our engineers also offer a number of services based on your unique requirements:

Construction

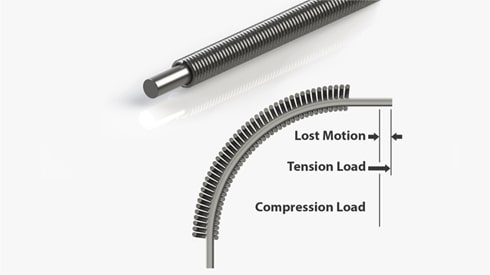

The basic components of a push-pull control cable consist of a solid wire or stranded cable contained within a conduit, also known as cable casing.

Substituting a flexible cable construction, over solid wire alternatives, allows the control cable system to tolerate tight bend radii. Additionally, an assortment of different cable fittings can be applied to terminate the cable at each end.

Loss of Motion

In a control cable system, the principal elements of lost motion, include backlash and deflection. Backlash is caused by the core member moving inside the casing with the change in direction of motion. It is a function of the clearance between the core and casing, and the total number of degrees of bend in the cable. This can be reduced by careful design. The other cause of loss of motion is deflection. Deflection occurs when the casing/conduit is not securely anchored in order to prevent compression or tension of the applied load.

Travel

The distance the core wire or cable traverses the conduit of a push pull cable assembly should be kept to a minimum. Too much cable exiting either end of the control cable assembly will result in an increase in friction and a decrease in output response. Additional issues like buckling can arise when too much cable exits the conduit because the conduit is keeping the cable in a rigid orientation. Therefore, the core wire or cable should not be >5˝ if possible and the linear speed of operation should be relatively low.

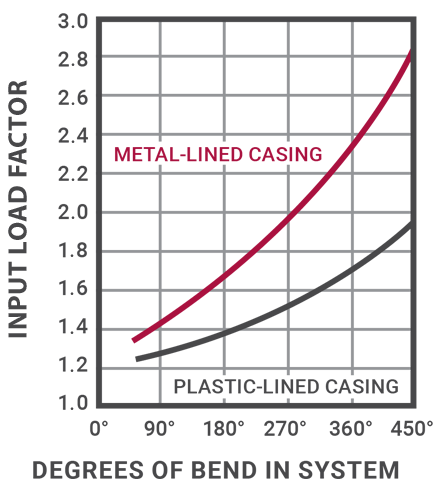

Input Load Factor

Input load factor is a crucial aspect to consider when designing and selecting push-pull control cables for various applications. It refers to the ratio of the input force required to operate the control system to the output force exerted by the cable. A low input load factor ensures smooth, efficient operation and reduces the risk of premature wear or fatigue in the cable assembly. By carefully selecting materials, optimizing cable construction, and considering factors such as cable routing and friction, engineers can achieve an optimal input load factor for push-pull control cables. This, in turn, contributes to improved performance, durability, and user satisfaction in a wide range of industrial and commercial applications.

I = Input Load

P = Output Load

F = Input Load Factor (from graph)

I = P x F

Example

Consider a control cable assembly with metal-lined casing requiring an output load of 6 lbs. Total degrees of bend in the system–270°. Input Load Factor from the chart–2.05. Input Load = 6 x 2.05 = 12.30 lbs.

Get your push-pull component needs met right the first time, every time with Sava.

Let's discuss your next project or get a quote today!