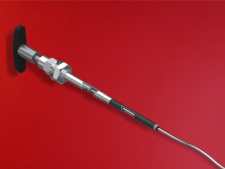

This intricate laparoscopic medical assembly has number of complex, customized machining operations that comprise its construction. A single production error, on even an infinitesimal scale, can and does compromise the part’s integrity. This is why Sava must perfect and validate each stage of production to ensure a predictable quality operational process, whether it’s the first or millionth part to come off the production line.

Custom-machined male and female threads, annealed for flexibility and durability, swaged fittings and ball and shank on 7x7 stainless steel cable

MedTech Cable Insights

As mentioned above, the slightest production fault, in any phase of production, can cause the parts to fail in the field. Sometimes, the sophistication of these tiny MedTech cable assemblies can hide their manufacturing elegance in plain sight, and this assembly is no different. The complexity of this particular endosurgical mechanical cable assembly is evident for a few reasons. For one, the assembly contains both female and male threads, which had to be custom-machined in-house. Furthermore, the assembly needed to be annealed, which makes the wire rope more formable, because annealing softens the metal to allow it to enjoy improved ductility and reduced brittleness. The custom-made fitting was swaged to the 7x7 stainless steel cable, and from there, the threads were applied to the fitting. Finally, a ball and shank fitting was swaged to the opposite end of the cable.

This advanced MedTech wire rope assembly required nine unique machining operations just to complete a single part, meaning constant care and attention must be applied throughout production, ensuring that any part, selected at random, possesses a quality and precision that’s indistinguishable from any other part, also selected arbitrarily.

Complex Cable Solutions®

Carl Stahl Sava Industries implements stringent quality controls and precise machining techniques. Each phase of production is closely validated by trained quality personnel to certify that the standards required by regulatory bodies like the FDA, as well as those set by the device makers themselves are all met. Sava’s Machining Supervisor, Joe Falletta, emphasizes the necessity of executing each operation flawlessly, no matter if we’re producing a single assembly or 1,000,000.

Results: Safer Procedures

The result of Sava’s rigorous manufacturing processes is a reliable and highly precise laparoscopic cable assembly that aids surgeons during GYN and bariatric procedures. By holding the laparoscope steady, it effectively acts as a third arm for the surgeon, enhancing the doctor’s occupational and ergonomic functionality during the procedure. This makes it less invasive, which assures patients a quicker return to the life they were enjoying before surgery was required. The ability of Sava’s machining talent to produce such a well-designed cable assembly underscores Carl Stahl Sava Industries' commitment to quality and excellence in medical device cable production.

If you need custom assembly for surgical robots or any other related product, you can always count on us. Sava’s engineers will recommend the right cable for any application. Contact us and have all your questions answered.