Cable Pulleys are Simple Machines

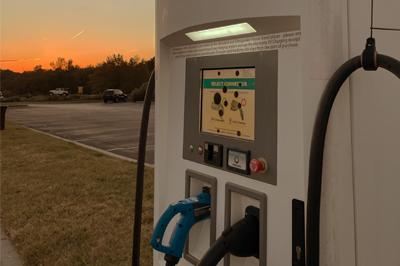

Cable pulleys have been used by virtually every person who has gone to a gas station to fuel their vehicles. Cable pulleys are simple machines used in mechanical cable and wire rope applications where reducing effort is necessary as the cable completes a radius over a motion control system. In the case of fueling up one's car, the pulley system assists by spreading heavy loads across the distance between the fueling unit and a car's fuel dispenser. In this case, the load also typically traverses a bend radius or radii. In the case of EV charging stations, similarly to gas station pumps, the pulley at the top of the charging unit allows a cable-made tether to glide effortlessly around the pulley and support the weight of the charging cable.

Browse Our Entire Selection of Cable Pulleys

Think about how many times we pumped our gas throughout the lifespan of a car. In that scenario, the hose and nozzle are taken from the pumping unit and essentially dragged by your hand to the gas tank receptacle. The abuses these fueling systems experience are enormous. Whether obvious or not, that nozzle is tethered to a stainless steel mechanical cable that ensures the unit retracts to its resting position, without undue strain imposed on the hose. This retracting action is largely achieved through the pulley system accommodating the loads to actuate motion.

With gas prices fluctuating and people becoming more environmentally conscious, more than 52% of vehicle owners are looking for electric vehicles according to the EY Mobility Consumer Index 2022. So, for people who switch from gas vehicles to electric, as soon as they pull up to the charging station, they may use something incredibly familiar: a pulley system.

This is because the tried-and-true method of using a pulley and counterweight system works so well, and it is so simple, that there is little reason to improve upon it.

Having a pulley system is necessary to retract the charging cord, while allowing it to be held high, reducing exposure to common environmental risks, like being run over by a car or laying near ground water.

Mechanical cable performs a vital service to the charging unit itself by preventing the user from leaving the power source laying on the ground. The pulley system essentially disallows this from happening by returning the charging assembly to its initial, resting position.

The mechanical cable used in the pulley-counterweight system is typically no larger than 0.25” in diameter, which is sufficient for compatibility with the pulley grooves and supporting the application loads. The cable is attached to a pulley, which is attached to a clamp, which is then attached to the charging hose assembly. The counterweight inside of the charging station allows the cable to retract back to its resting position.

While there are a variety of pulleys used in the design and manufacture of EV charging stations, the right pulley is determined by a host of application variables that differ one system to the next. Among some of the pulley choices used commonly in the development of EV charging stations include nylon pulleys or Delrin pulleys, both of which are a type of plastic and tolerate outdoor environments quite well. Zinc-plated steel pulleys are alternative solutions, which also offer excellent durability. However, because of their steel content, zinc-plated steel pulleys could be exposed to rust over time. To avoid common errors in pulley selection in general, it’s best to consult a pulley expert while developing an EV charging station.

Pulley Materials

DELRIN PULLEYS

Delrin pulleys, which are produced from polyoxymethylene plastic, are a good choice for outdoor EV charging stations for a variety of reasons. Delrin pulleys, for instance, are lightweight, which imposes very little additional load on system components. Delrin pulleys are also easy to manufacture, being that they are molded and can be produced at quick intervals and high volumes. They also possess a low friction coefficient, due to their natural lubricity, which equates to less wear-and-tear on the mechanical cable itself. What’s more, Delrin pulleys are both temperature-stable and possess exceptional electrical insulation, meaning that they have a high melting point compared to other plastics and do not conduct electricity.

One of the many challenges facing EV charging stations is that they are exposed to the elements. It is imperative, therefore, that critical components are resistant to weathering. Delrin pulleys have an unparalleled resistance to moisture, gasoline, sunlight, solvents, and other chemicals. If the EV charging station is located anywhere near a gas station, for example, the resistance to gasoline and gasoline vapors is vital to the long-term functionality of the charging unit.

Finally, Delrin pulleys have greater mechanical strength and rigidity, as well as a higher fatigue rate, unmatched by other plastics. This is especially important because commercial-grade EV charging stations are meant for multiple vehicles at a time, so the cycle count of the pulley system will be high and the unit abused by users, making it crucial that pulley materials can tolerate such hostile conditions.

Zinc-Plated Steel Pulleys

Metal pulleys, such as those made from zinc-plated steel, are also a good option when developing an EV charging station. For one, the zinc-plating offers the steel a layer of protection against particulates present in harsh weather conditions, such as moisture. Additionally, zinc-plated steel pulleys have higher load capacities based on their load bearing, so they can handle heavier cables. Bear in mind, however, that since steel pulleys have a higher friction coefficient, they can also wear away the cable sooner than plastic alternatives. Furthermore, the zinc-plating will also wear over time, which exposes the pulley to rusting over time. To counter this, in steel pulleys, it is best to lubricate the bearings as necessary.

In addition, Zinc-plated pulleys work incredibly well with smaller diameter cable. Their radial capacity can hold up to 410 lbs at 50 rotations per minute, although efforts should be made to avoid overloading the pulley because it will result in catastrophic failure for both the pulley and the charging system itself.

Zinc-plated pulleys have an additional protection: their bearings can be shielded.

Bearings are mechanical devices, used to assist rotational motion, offering a significant reduction in friction. Shielded bearings go a step further. Like protecting dry hands with moisturizers, shielded bearings protect bearing components from external environmental hazards. Depending on the type of bearing, those found in zinc-plated steel pulleys may require manual lubrication. But this is not typical because shielded bearings are unexposed due to their shielding.

In addition, Zinc-plated pulleys work incredibly well with smaller diameter cable. Their radial capacity can hold up to 410 lbs at 50 rotations per minute, although efforts should be made to avoid overloading the pulley because it will result in catastrophic failure for both the pulley and the charging system itself.

Cable Pulley Bearings & Bushings

Zinc-plated pulleys have an additional protection: their bearings can be shielded.

Bearings are mechanical devices, used in cable pulleys to assist rotational motion, offering a significant reduction in friction. Shielded bearings go a step further. Like protecting dry hands with moisturizers, shielded bearings protect bearing components from external environmental hazards. Depending on the type of bearing, those found in zinc-plated steel pulleys may require manual lubrication. But this is not typical because shielded bearings are, by their very design, unexposed - or shieled from harmful particulates present in the field.

CABLE PULLEY BEARING SELECTION

Just as important as selecting the right pulley is choosing the proper bore & bearing type. While a bore is the hole in the center of the pulley, a bearing and a bushing, as discussed previously, significantly reduce frictional forces. A plain bore, centered hole, bushing, needle roller bearing, or ball bearing are all examples bore and bearing options.

Different bore and bearing options will allow for varying results in friction reduction, pulley life, cable life, speed, and wear.

No matter what kind of car you drive, eventually its fuel source is going to need to be replenished. Electric vehicles are growing in popularity, and as such, so is the frequency with which people use EV charging stations. Pulleys are an integral component to how we keep our lives moving in the conveyances we depend upon daily.

Carl Stahl Sava Industries is an industry leader in the design and manufacture of pulley systems. Contact our engineering and sales team to make a more informed decision and to begin designing your pulley solutions today!

Charging Station Image Credit: Maryland Department of Transportation