Cutting stainless steel cable can be done with electricity, industrial-caliber blades that are powered by either pneumatic or hydraulic force, and, yes, even the blades of a hand tool. But, if cutting a cable was the only objective, then the least expensive and speediest approach would do nicely every time. However, cutting stainless steel cable is anything but a simple matter of severing the cable and swiftly moving on to the next manufacturing step.

Because each of these three cable-cutting methods brings with it unique benefits and limitations, it’s important to analyze which approach to cutting cable yields the ideal outcome. Now typically, one might surmise that the cutting approach that produces the highest quality cut end would be the best, right?

Not necessarily.

You see, each cut length of stainless steel mechanical cable serves a unique function.

Some are used to simply support a static load or perhaps transmit motion across a distance. While in other situations, stainless steel cable is implantable and, consequently, used in surgical systems like the ones used to replace a loved one’s hip joint. So, cutting stainless steel cable isn’t merely an artless matter of cutting the cable and moving on. Rather contrarily, it’s a precision process of determining what the cut length needs to achieve in its final production environment that informs the proper cutting method.

Determining the Proper Cable Cutting Method

Taken as an example, if the stainless steel cable’s application and/or design does not require the wires to be fused together at the cut end, then cutting the cable with a tool as rudimentary as a hand cutter may suffice. In this use case, the hand cutter does the job as expected, but more importantly, as the designing engineer or operator intended. Simply put, the cable’s design requirements, again in this scenario specifically, are not concerned with frayed wires at the cut end. Accordingly, the “quality” of such a cut would likely be characterized as high because it met the cable’s cutting requirements.

On the other hand, if cutting the cable with blades causes unwanted wires fraying at the cut end, the cut's " quality " would likely be low. After all, even only slightly unraveled wires at the cut end will introduce difficulties in inserting the cut cable end into mating components, such as a ball or sleeve fitting. Even if the cable’s entire complement of wires fed into the ball fitting’s thru-hole, matters of integrity may come into question. The presence of less apparent wire separation, often called “bird caging,” which is the presence of any degree of deformation of the wires from their manufactured helical geometry, may weaken the entire cable assembly due to the insufficient cable surface area available to make requisite contact with the ball fitting.

So, while one can successfully fuse cut (with electricity), or blade cut stainless steel cable, the quality of the cut is a subjective matter determined by the application’s requirements, not by the presence of a cleanly sheered length of stainless steel cable.

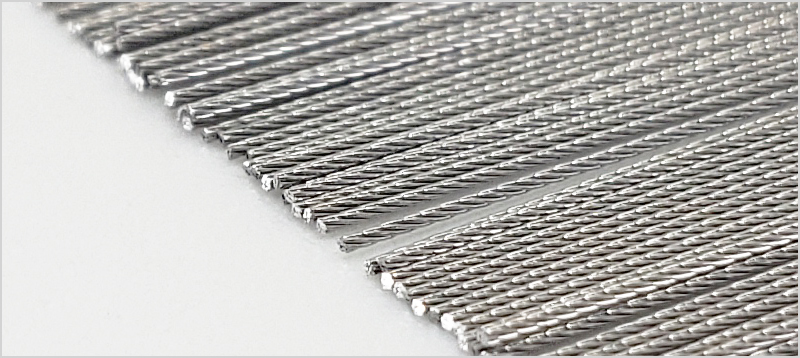

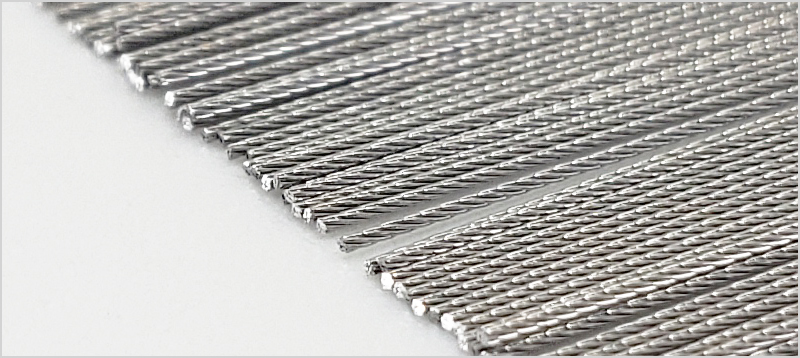

The Behavior of Stainless Steel Cable

Without understanding the chemical composition of stainless steel, one may not be prepared for the material’s behavior during cutting operations. So, before we discuss methods used to cut stainless steel cable, one must understand the fundamental physical manner of stainless steel cable.

304 stainless steel, among the most common grades used in the production of stainless steel cable, is made up of approximately 72% iron (Fe), 18% chromium (Cr), and 8% nickel, among other elements in smaller percentages. What gives stainless steel cable its naturally springy disposition is the presence of chromium and to a lesser degree, nickel. Chromium possesses a high elastic modulus, meaning it’s naturally pliant, let’s say, like a rubber band. Pulling on a rubber band just enough to change its natural resting geometry, doesn’t change its natural form once the pulling stops. Similarly, contorting miniature stainless steel cable results in the same outcome: a stainless steel cable that returns to its manufactured geometry.

Nickel also has a high elastic modulus.

Combined, the chromium and nickel content of stainless steel cable makes it both incredibly strong, but also as notable, exceptionally pliable too.

Cutting cable that behaves in such a geometrically restorative manner means the wires twisted into their helical orientation are at risk of separating when cut. For this reason, using a hand tool, without taking additional manufacturing steps before cutting, will likely result in destroyed stainless steel cable. And setting aside the disappointment it would be to destroy cable by using inappropriate cutting methods, the cost of the cable itself is reason enough to ensure the proper pre-cutting steps are executed.

Browse Sava's Stainless Steel Cable Options

Sava Has Been Making Stainless Steel Mechanical Cable for Over 50 Years

Cutting Stainless Steel Cable

with a Hand Cutter

Ironically, both hand-cutting and fuse-cutting stainless steel cable generally adhere to the same basic principles of physics.

Extreme heat, for instance, is required to fuse cut stainless steel cable. Likewise, if the operator seeks to avoid fraying of wires at the cut end, cutting the same cable by hand requires heat as well. But in the case of fuse cutting, also sometimes called electrocutting, the concentrated burst of electricity that passes through the cable produces enough heat to soften the cut wires enough to fuse them together as the simultaneous cut is being made.

But if the melting point of stainless steel is somewhere between 1,400 and 1,450 degrees Fahrenheit, how then, with a hand cutter, would one produce the heat required to achieve a fused end? While this article does not address methods for producing this degree of heat, nor does it purport to suggest a safe method to apply by hand, heating the stainless steel cable to comparable temperatures is adequate to soften the material sufficiently to fuse the cable’s wires together, even if the cutting is done with a hand tool.

But be warned that, while one can produce adequate heat to prepare the cable for hand cutting, this manual approach to cable cutting presents many challenges.

For one, if a hand is literally the source of the forces used to cut the cable, then stationary guides and measurement rigging should be in place to ensure cut lengths meet the designed tolerances, one cut length to the next. What’s more, cutting stainless steel cable by hand also risks variability in the shape and geometry of each cut end. If fusing the wires together is also essential, but the cut itself varies in angle and appearance, cut-to-cut, then difficulties may emerge mating the newly cut length of stainless steel cable with an eyelet, crimp sleeve, or other common mechanical cable termination.

Fuse Cutting Stainless Steel Cable

The fuse cutting method is the preferred way to cut stainless steel cable.

A fuse cutter passes a short, controlled burst of electrical current directly through the cable, which instantaneously cuts the cable and fuses the wires at the cut end together using the molten cable material the electrical heat produced. This operation is typically conducted by a mechanical cable manufacturer.

What makes this approach the best choice is that, for one, cable manufacturers possess the cable cutting experience to ensure that each cut end is identical to the last. This becomes critical when producing thousands or even millions of cut-length pieces of stainless steel cable. Secondly, a cable maker is also able to automate the entire operation, whereby, in ideal cases, cables are cut, then bundled and even packaged for shipping or prepared in lot quantities for the next manufacturing step.

Mechanically Cutting Stainless Steel Cable

Somewhat less ideal than fuse cutting, but still well suited to cutting stainless steel cable, is mechanical cutting.

Like a hand cutter, blades are used to pass through the cable, severing it instantly. Powered by pneumatic or hydraulic energy, mechanical cutting is done using an industrial cutting machine that applies massive forces to the blades as they pass through the cable. In some cases, the forces required to cut miniature stainless steel cable, measured against the forces that human hands produce, may be too far apart to achieve the desired cutting outcome. For instance, many hand-held cable cutters are squeezed, like pliers, using one’s hand. Most of these tools stipulate that mechanical cable up to 0.25” is the maximum diameter suited to such methods. In the small, miniature, and ultrafine cable space, an industrial-grade mechanical cable cutter can be adapted to meet the cutting forces required of the cable, no matter its diameter, while the same cannot be said of one’s hands, as cable diameters increase.

Similar Cutting Methods does not Mean Identical Cutting Methods

As one can see, cutting stainless steel cable is an exercise not merely in achieving a clean, precise cut length. The goal is to cut the cable perfectly every single time and do so in a manner that honors the cable’s design and ultimate application requirements. Ask Sava’s cable experts how precisely they believe one should cut stainless steel cable. Chances are good our engineering team has seen your cutting requirements and can advise on the smartest, most cost-effective, and highest-quality approach to manufacturing cut lengths of stainless steel cable.