Nylon pulleys are used virtually anywhere a load needs to be transmitted over a distance.

This specific variety of mechanical motion is fundamental to countless motion control systems and thus, the nylon pulley is a staple among numerous applications and industries. What makes nylon pulleys, known as a simple machine, so ubiquitous a fit for mechanical motion applications is the material used to produce the pulley. Pulleys of this variety yields the system into which it is deployed the durability, loadbearing and longevity benefits that are unique to pulleys made from nylon.

Understanding that all pulleys are used to decrease the forces required to lift or hold a load, and/or distribute a load across a distance, nylon pulleys, comparatively speaking, offer benefits that other pulleys simply cannot.

And it is in a nylon pulley’s broad array of advantages that it achieves its equally broad, comprehensive appeal.

Explore Sava's Entire Line of Nylon Cable Pulleys

Trust our 50+ Years of Manufacturing Expertise

Like the LP Series pulleys Sava produces, nylon pulleys contain a material known as molybdenum disulfide or MoS2, which is a combination of molybdenum and sulfur. Known as a solid lubricant, the MoS2 content in nylon pulleys helps deliver reduced friction and wear between mating components. Furthermore, MoS2 provides nylon pulleys with exceptional corrosion resistance, while also being capable of supporting heavy loads and by extension, a long lifespan in the field.

Even more, because MoS2 is a lubricant, nylon pulleys are at less risk of deformation over time, which ensures wire rope contacting nylon pulleys doesn’t expose the pulley to harmful frictional forces that could deform the pulley and/or damage wire rope.

Bore Condition Options

Like steel pulley options, which can be purchased with a vacant bore hole, nylon pulleys can too.

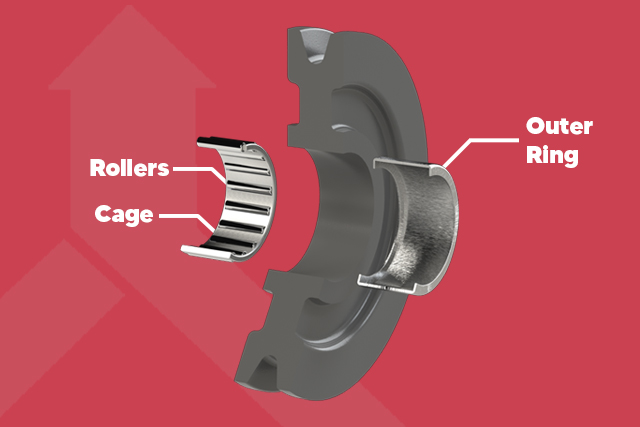

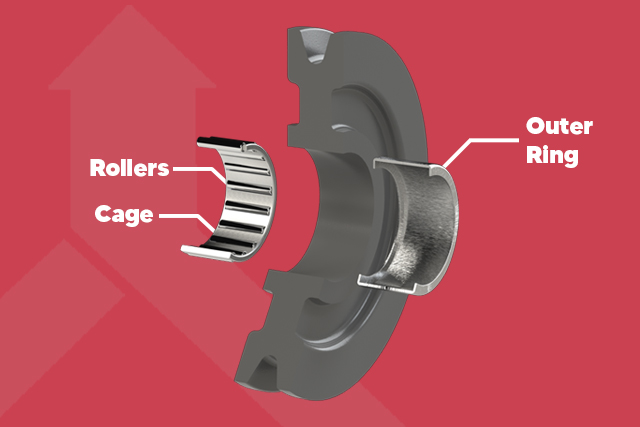

Known as bore condition, nylon pulleys can be equipped with either a bearing assembly, a bushing, or a plain bore. Among the most common bore conditions are those produced with a needle roller bearing assembly, which are cylindrically-shaped bearings designed to distribute, like the pulley itself, the load the pulley is shouldering.

Needle Roller Bore Conditions

As said, pulleys that contain a needle roller assembly evenly disperse the burdens of a pulley’s load. But they also reduce the lateral movement of the pulley because this variety of bearing assembly is designed to, among several features, reduce noise, vibration, and mechanical anomalies while in motion. The precision with which a needle bearing assembly rotates, by its very nature, ensures higher rotational efficiency of the pulley itself because needle bearing bore conditions practically eliminate frictional forces in any direction. Needle bearing assemblies can be exposed or sealed, the latter meaning that the bore condition can be fully hidden from damaging outside environmental consequences like water and dust.

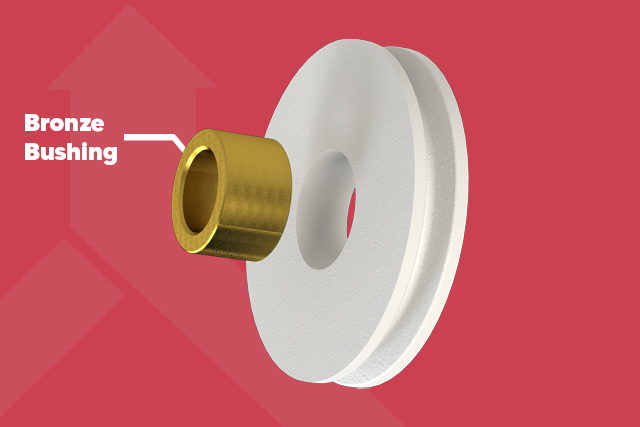

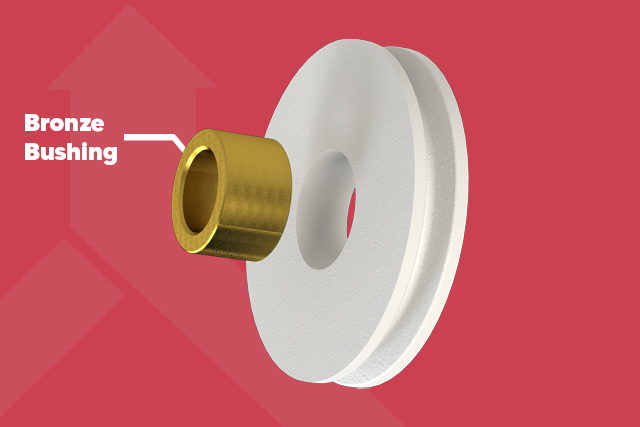

Bronze Bushing Bore Condition

Nylon pulleys can also be equipped with a bronze bushing, which, due to bronze’s natural softness, behaves as a sacrificial wear surface. This component allows the bushing to absorb frictional wear while protecting the pulley itself from the same. Furthermore, because bronze, like MoS2, is a natural lubricant, frictional forces introduced to the bushing wear slowly, ensuring a long-lasting lifespan. Combined with the natural corrosion-resistant properties bronze possesses, nylon pulleys with a bronze bushing are another common bore condition used across many pulley system applications.

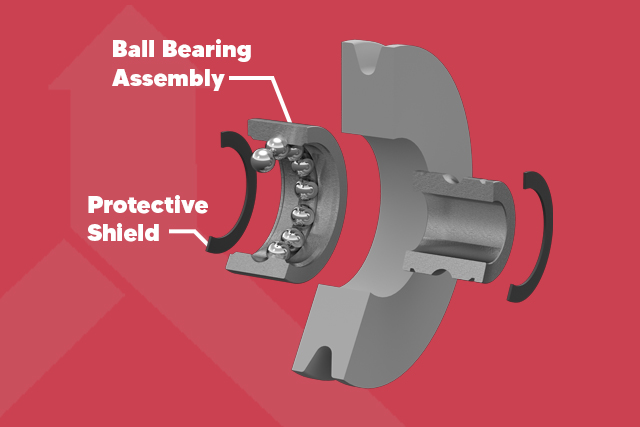

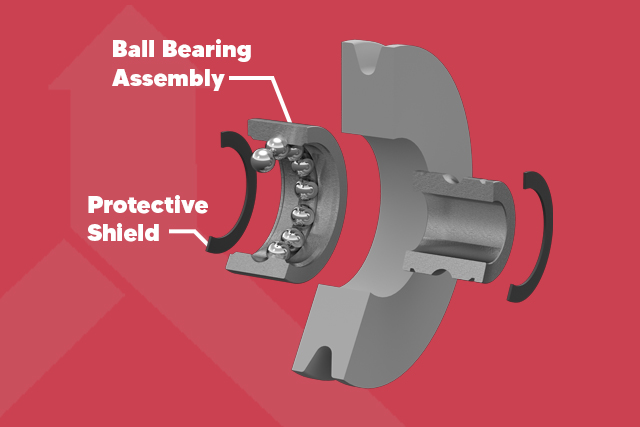

Ball Bearing Bore Condition

Another popular bore condition is the ball bearing assembly. Smooth rotational support, paired with increased load-bearing potential, compared with bushings, for instance, and one can see why ball bearing bore conditions are ideal. For one, ball bearing bore conditions help support greater loads than let’s say a bushing because ball bearings, like needle bearings, reduce unwanted lateral movement in the nylon pulley.

Additionally, because ball bearing bore conditions maintain a strict alignment between the shaft (inserted components) and the pulley, rotational accuracy is also improved, again, when compared with a bushing solution.

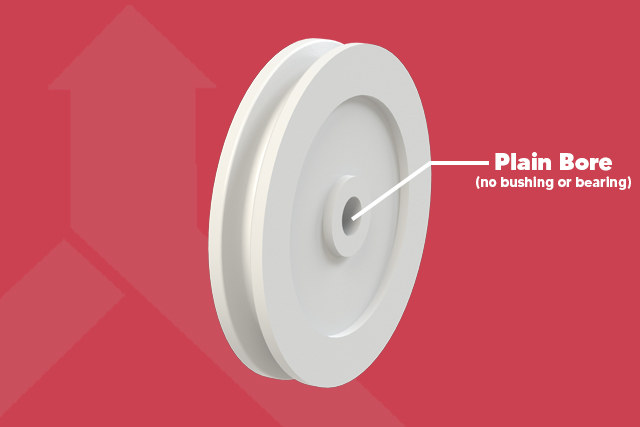

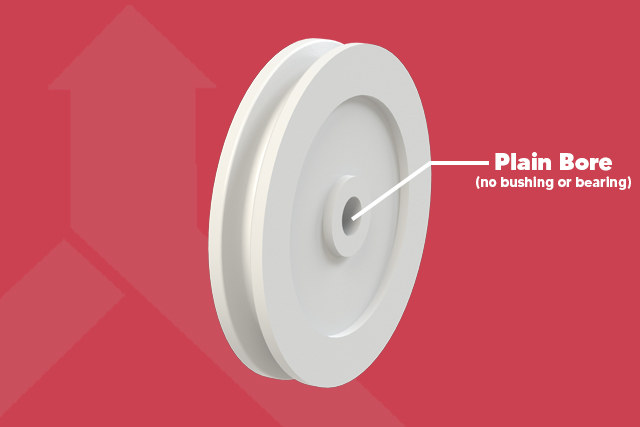

Plain Bore or Unbored Conditions

In plain bore nylon pulley condition, the pulley is simply manufactured with a vacant bore hole. This bore condition introduces the nylon pulley itself to frictional wear because it doesn’t benefit from an added protective shield like those found in bearing assembly bore conditions. Although the MoS2 content of nylon pulleys provides the pulley with a layer of natural, solid lubricant, a plain bore condition can be popular in use cases where the loads are marginal, and the frictional taxation is minimal.

In an unbored bore condition, the pulley is produced with a solid center, leaving the pulley’s purchaser to decide what bore condition suits their unique application requirements.

Understanding Nylon Pulleys

As mentioned, nylon pulleys can be found everywhere pulleys are supporting and/or transferring a load, including medical devices, industrial equipment, and even our cars, trucks, planes and boats.

But the many industries that rely on nylon pulleys become rather fascinating due largely to how popular they are for different reasons, from one use case to the next.

Take, for instance, materials handling duties.

Nylon pulleys are used commonly among materials handling applications, like hoppers or conveyor belts because nylon pulleys are quite strong, resist wear well over time, and as also stated above, are resistant to many common corrosive conditions that may destroy other pulley material types, such as those made from zinc plated steel. Their resistance to wearing down is also impressive, given nylon is a synthetic polymer. So, nylon pulleys not only support considerable loads, but their strength is also complemented by a natural tolerance to abrasive materials and harsh operating conditions. This resilience helps prevent wear and deformation, which are common issues in other pulley materials.

And because nylon pulleys are relatively lightweight, compared with their loadbearing capacities, they tend to add far less system weight, compared with steel pulleys. Plated steel pulleys, by comparison, are far heavier, which places an increased burden on mating components, and the overall weight of an entire system.

Another reason nylon pulleys are ideal for material handling is that they are incredibly adept at withstanding the perpetual, unstopping movement involved in transporting materials or goods over a distance.

Once again, the MoS2 material impregnating nylon pulleys means less wear, over the conveyor systems meant to operate 24 hours per day, seven days per week, 365 days per year. Understanding that conveyor systems are often in operation for decades before obsolescence, it becomes plain to see why the nylon pulley is so coveted among a conveyor’s critical components.

Nylon Pulley Applications

Although this article singles out conveyors as a common use case for nylon pulleys, the list of applications using nylon pulleys is vast.

Winches and pullers, for example, use nylon pulleys for many reasons, but chief among them is that they do an exceptional job mitigating the consequences of frictional forces. Winches are in a constant state of frictional motion that exists between a nylon pulley’s groove and the system’s mating wire rope. Whether the wire rope is coated or bare, no matter the particulars of a pulley system, friction is a common threat to components sharing the same surface areas. As mentioned, the lubricating properties of MoS2, assure a nylon pulley smooth, fluid surface contact with the cable traversing over, under, and around a pulley groove.

Another common application that uses nylon pulleys is cranes and hoists. Like winch applications, which may be most often moving forward and backwards, the frictional forces of wire ropes moving up and down in hoisting operations means that similarly, the pulley must tolerate the ceaseless movement of wire rope crossing the surface of a pulley groove. Combined with the known strength benefits of nylon pulleys, and their lifting capacity in this case, hoisting a load up and down requires not only a pulley with natural lubricating characteristics but also one that can bear significant loads.

But a word of caution: nylon pulleys are not meant to support the same loads as say, a zinc-plated steel pulley. Although the steel alternative is going to shoulder far more load, they are also more expensive, far heavier, and corrosion resistance will be a steady concern as the zinc plating fades over time or is otherwise damaged amid hostile environments.

By way of comparison, nylon pulleys that are about 6” in diameter (0.1524 mm) can handle a load up to approximately 1,600 lbs. or about 726 kg, without a bearing or bushing assembly. Introducing a bearing or bushing assembly to a nylon pulley will either fix the load-bearing capacity at its maximum or reduce it depending upon the loads the bore hole assembly can tolerate. Conversely, A 3.5” (0.0889 mm) plated steel pulley, again as a way of comparing the two, is designed to support wire rope with a breaking strength as high as 12,000 lbs. (5443 kg).

Other Nylon Pulleys

Not all nylon pulleys are produced using molybdenum disulfide. This is an important distinction of which to be aware. Such nylon pulleys are routinely used in low-friction, slow-moving applications. To help readers conceptualize the different behavior characteristics of both the nylon pulleys with MoS2 and those without, review the chart below.

Nylon Pulleys Molybdenum Sulfide Comparision Chart

| FEATURE | PULLEYS WITHOUT MOS2 | PULLEYS WITH MOS2 |

|---|---|---|

| Lubrication | Not as important | Important |

| Wear resistance | Lower | Higher |

| Corrosion resistance | Lower | Higher |

| Cost | Less expensive | More expensive |

| Applications | Low-speed, low-load | High-speed, high-load |

Ask an Expert

Sava’s engineers possess extensive expertise in the diverse applications of nylon pulleys. They have a thorough understanding of the specifications across our LP Series Pulleys, ensuring each pulley is suited for its intended use. To discover more about our capabilities, contact us today.