What is a Pulley?

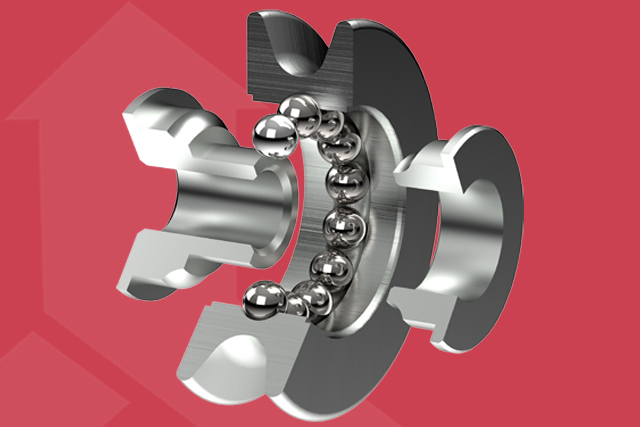

A pulley, also known as a sheave, is a simple machine comprised of a grooved, rim wheel where a length of wire rope rests, an axel located in the center hole, typically inclusive of a lubricated bearing assembly to facilitate the wheel’s smooth rotation, and finally a pulley bracket that holds the pulley stationary. Pulleys are used to either reduce the forces required to lift or hold a load and/or distribute a load over a distance.

While there is some debate as to when and who invented pulleys, they are credited to the Greek scientist and inventor, Archimedes, though evidence of pulleys systems used during ancient Egyptian times conflicts with this chronology. Disputes aside, the sophisticated bearing assemblies these simple, but elegant machines use began to proliferate during ancient Roman times, and by the Middle Ages, were progressively improved through the annals of time.

Even Leonardo da Vinci kept journals and notebooks documenting his many pulley system inventions, which included cranes, elevators, and even flying machines.

Today pulleys are used quite literally everywhere in virtually countless pulling, lowering, and lifting machines used by us all in our daily lives.

Browse Sava's Plated Steel Cable Pulleys

Trust Sava's 50+ Years of Manufacturing Expertise to Find the Right Pulleys for Your System

How Do Pulleys Work?

As mentioned, pulleys are used to reduce the amount of force required to support a load and/or change the direction of force used to support or move a load.

A simple formula one can use to express how pulleys function would be Force Required = L / (P * W). In this equation, L equates to the load requiring force, divided by P, which is the quantity of pulleys used, multiplied by W, which is the quantity of wire ropes involved. As mechanical engineers introduce more mechanical cables and/or pulleys, the forces required are reduced.

To simplify how a pulley works, attempt to lift a 250 lbs. slab of marble off the floor by merely sliding your flattened hands beneath it and lifting upward. The forces required to lift the material by yourself, in an upward direction, would be equal to the weight of the marble. This example represents a motion system comprising one length of wire rope and a single pulley. Because only one pulley is in use, the load required is equal to that of the marble slab.

However, add five more people (or six pulleys in total), all lifting as you did, but distributed across the entire stone, and the forces required for each person to lift has been reduced to 41.66 lbs. Known as a mechanical advantage, a single length of wire rope fed through all six pulleys equates to 41.66 lbs. of force required per person (or per pulley), which is expressed as 250 / (6 * 1) = 41.66 lbs.

Fundamentally speaking, this is how pulleys work.

The six of you were used as pulleys to reduce the forces required to lift and support the marble without ever reducing the weight of the load itself. Pulleys, somewhat like our hands in this scenario, distribute a load over a distance.

Changing Directional Force

Pulleys change directional force too, which also lends to the ease with which a load can be lifted.

Using the marble use case further, imagine the slab needs to be dragged up a hill, and not merely just lifted off the ground. In this case, a single pulley could be stationed at the top of the hill, while positioning the operator at the bottom, alongside the block of stone. In this design, the operator would need to apply 250 lbs. of force, the weight of the marble, to move the stone up the hill.

But, if a second pulley was introduced to the system halfway up the hill, the load forces are in half.

With the introduction of a second pulley, pulling forces are expressed as 250 / (2 * 1) = 125 lbs., where the two pulleys, paired with a single length of wire rope cut the force required by half. Adding more pulleys would reduce the required pulling forces even more.

Plated Steel Pulleys

Zinc-plated pulleys, often known simply as plated steel pulleys, are pulleys (or sheaves) that are made from mild steel, which is typically < 0.25% carbon, that is electroplated with zinc to provide the pulley with a layer of corrosion-resistant protection from harmful elements like vapor. Because it does not contain common corrosion-resistant alloys like chromium, molybdenum, or nickel, low carbon steel, to which it can also be referred, quickly rusts as it is exposed to moisture, no matter how negligible the amount of condensation might be. For this reason, electroplating mild steel with zinc ensures the plated steel pulley durability and long-lasting lifespan that simply would be impossible to achieve were the pulley not plated.

But just because a plated steel pulley is produced with an electroplated zinc coating does not mean this specific variety of pulley is suited to applications where moisture is present. As a matter of fact, even only slightly damp conditions, over time, may wear down the thin coating of zinc in plated steel pulleys, exposing the vulnerable low-carbon steel material to hostile elements. When this happens, the pulley is vulnerable to oxidation (rust), as well as other common corrosive effects of condensation.

Plated Steel Pulleys: Common Bearing Design Configurations

While there are many plated steel pulley diameters, their physical distinctions are most apparent in their bearing designs. One to the next, plated steel pulleys look the same: they contain a groove and a center hole, which can also be called a through hole or thru hole.

What makes each plated steel pulley unique is its bearing design, however.

In plated steel pulleys, for example, the bearings are used to support the smooth turning of the pulley wheel within a motion system. So, as a cable moves over or around a pulley, the pulley wheel spins fluidly due to the lubricated bearing system contained in the center hole of the plated steel pulley.

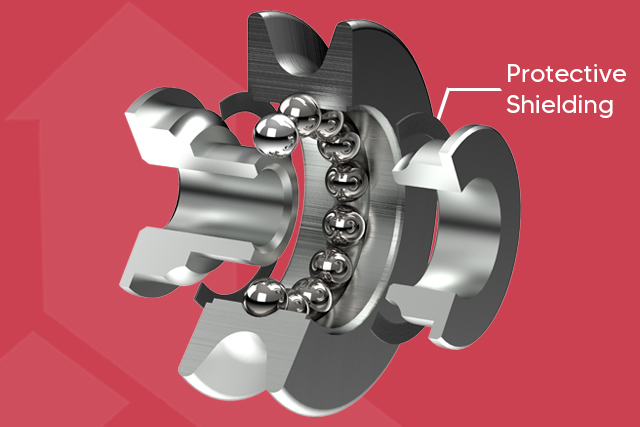

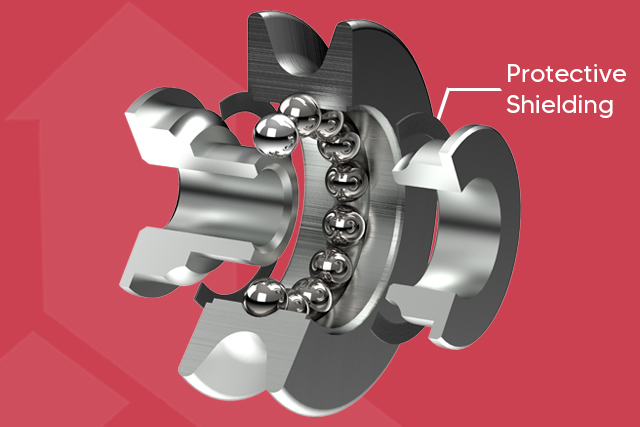

The most common bearing assembly in plated steel pulleys is a ball bearing design. Like Sava’s CP plated steel pulleys, these sheaves contain a single-roll ball bearing assembly comprised of a single, linear string of ball bearings, distributed at a defined spacing by an interlinked mating assembly known as a separator. A separator is a thin, steel interlocking housing assembly that wraps around each ball and includes a hinge-like connector between balls. Together, the separator traps each ball into position and keeps the entire ball bearing assembly smoothly rolling as the pulley’s wheel is manipulated by a length of wire rope.

Plated steel pulleys using a single-roll ball bearing assembly are commonly used for slow-speed applications.

In the small and miniature mechanical cable space, other bearing configurations may include less popular pulley designs, such as those using needle roller bearing varieties, which are a series of bearings organized linearly and cylindrical in geometry. These bar-like bearing designs allow for the plated steel pulley to move at high speeds without concern for failures at the bearing location. The stability that needle bearings provide is due in part to their broad footprint. So, unlike ball bearings, which are round, as their name suggests, needle bearings are tubular in shape, allowing more surface material to maintain contact with critical motion control components of the pulley, like the outer and inner ring races (i.e., race), as well the pulley’s two shoulders. Although other bearing configurations may be available for plated steel pulleys for small and miniature wire rope, this article focuses on the most common bearing design: single-roll ball bearings.

Shielded and Unshielded Plated Steel Pulleys

Shielded Plated Steel Pulleys

As mentioned, shielded pulleys comprise ball bearings that are sheltered from the outside environment -- most often by a thin wall-like layer of plastic, which seals in the bearing assembly, thus shutting out harmful particulates and contaminants like dust, dirt, and debris. Additionally, shielded bearing assemblies also protect the pulley from corrosive elements like moisture, which could damage the delicate, lubricated movements of the bearing assembly. However, because the shielding is most often made of plastic, it may be vulnerable to other harmful conditions, such as excessive heat or other extreme climates. For these reasons, it is critical to ensure that a shielded, plated steel pulley is deployed in applications where punishing temperatures are not present. While other shielding materials exist within the family of plated steel pulleys, like bronze and stainless steel, for example, they are less common among applications where small and miniature wire rope is in use.

Unshielded Plated Steel Pulleys

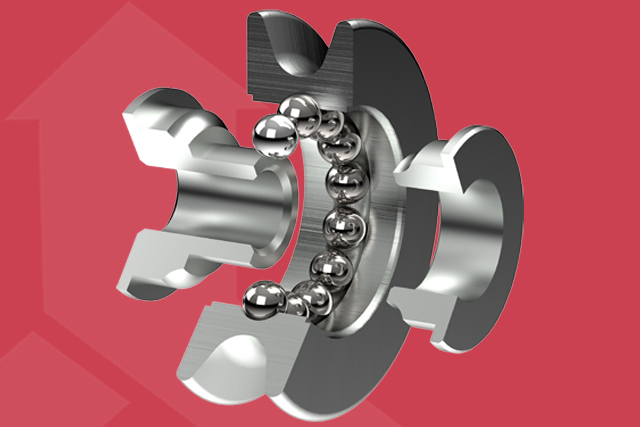

Unshielded plated steel pulleys are the exact reverse.

The ball bearing assembly in unshielded, plated steel pulleys is fully visible. This bearing design is popular in applications where exposure to particles and hostile temperatures are not a pressing concern. But use caution with unshielded pulleys. The ball bearing assembly is plain to see, which means any unwanted artifact may come in close or worse direct contact with the lubricated system of bearings that, if exposed to virtually any destructive forces, could cause the entire motion system to fail.

Careful Cable and Other Considerations

When choosing a plated steel pulley, it’s critical to understand groove diameter, both inner and outer. Likewise, other vital measurements, for example, such as bearing thickness, mating cable diameter, cable material, and many other variables also need to be considered. For instance, plated steel pulleys are not compatible with bare wire rope and miniature mechanical cable. Because the electroplating operation deposits only between 2 and 10 micrometers of zinc ions onto the surface of the low-carbon steel, the slightest damage to the surface of the pulley will expose it to outside elements.

The exact diameter of the zinc coating is determined often case-to-case, but by comparison, red blood cells are approximately 10 micrometers in diameter. So, the zinc applied to plated steel pulleys is so thin that the slightest metal-to-metal contact will irreversibly damage the corrosion-resistant properties of a plated steel pulley.

Once any amount of condensation contacts imperfections in the protective zinc coating, oxidation, and later perhaps failure of the pulley in the field may occur.

This is why plated steel pulleys are typically used with nylon-coated cable. Coated cable is rubbery in texture and is therefore a forgiving surface with which to make contact with a plated steel pulley.

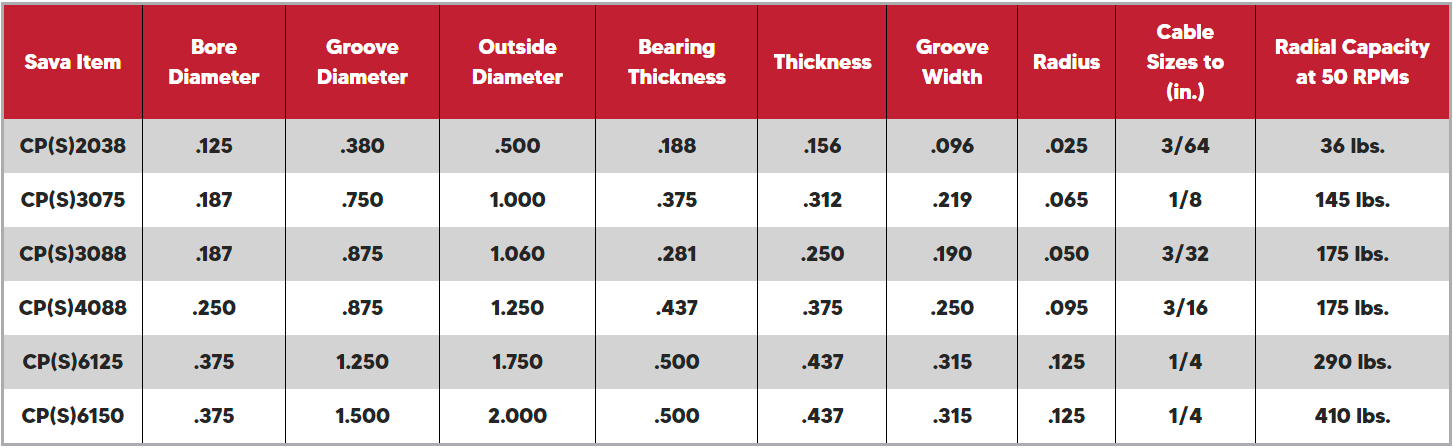

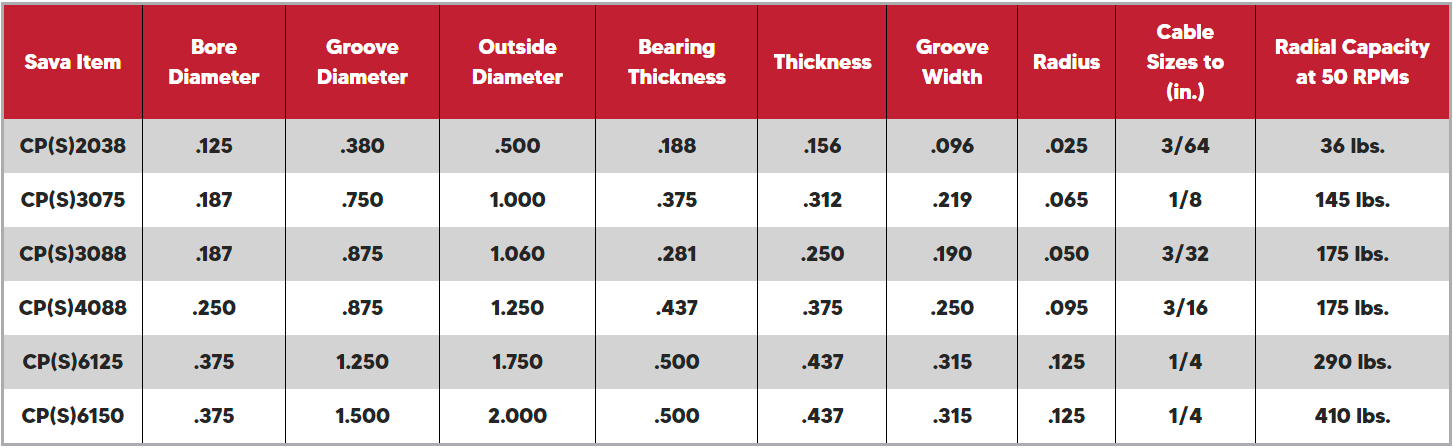

Technical Specifications

Understanding the technical specifications is crucial when evaluating plated steel pulleys. Below is a detailed table outlining the specifications of the CP and CPS series pulleys.

Ask an Expert

Plated steel pulleys are a simple machine, sure, but there is nothing simple about choosing the correct one for your motion control application. Ask the engineers at Sava to guide you through the pulley selection process. Doing so will ensure your pulley system shoulders the load as planned, as expected without surprising failures.

| Sava Item | Bore Diameter | Groove Diameter | Outside Diameter | Bearing Thickness | Thickness | Groove Width | Radius | Cable Sizes to (in.) | Radial Capacity at 50 RPMs |

|---|---|---|---|---|---|---|---|---|---|

| CP(S)2038 | .125 | .380 | .500 | .188 | .156 | .096 | .025 | 3/64 | 36 lbs. |

| CP(S)3075 | .187 | .750 | 1.000 | .375 | .312 | .219 | .065 | 1/8 | 145 lbs. |

| CP(S)3088 | .187 | .875 | 1.060 | .281 | .250 | .190 | .050 | 3/32 | 175 lbs. |

| CP(S)4088 | .250 | .875 | 1.250 | .437 | .375 | .250 | .095 | 3/16 | 175 lbs. |

| CP(S)6125 | .375 | 1.250 | 1.750 | .500 | .437 | .315 | .125 | 1/4 | 290 lbs. |

| CP(S)6150 | .375 | 1.500 | 2.000 | .500 | .437 | .315 | .125 | 1/4 | 410 lbs. |